How a Lithium Battery Storage Container Helps with Factory Power Demand Management

For many factories, electricity is one of the biggest costs. Production lines, lighting, air conditioning, and heavy machinery all need a lot of power. And it’s not just about how much electricity you use — it’s also about when you use it. If your demand spikes at certain times, your utility bill can shoot up. This is where a lithium battery storage container comes in.

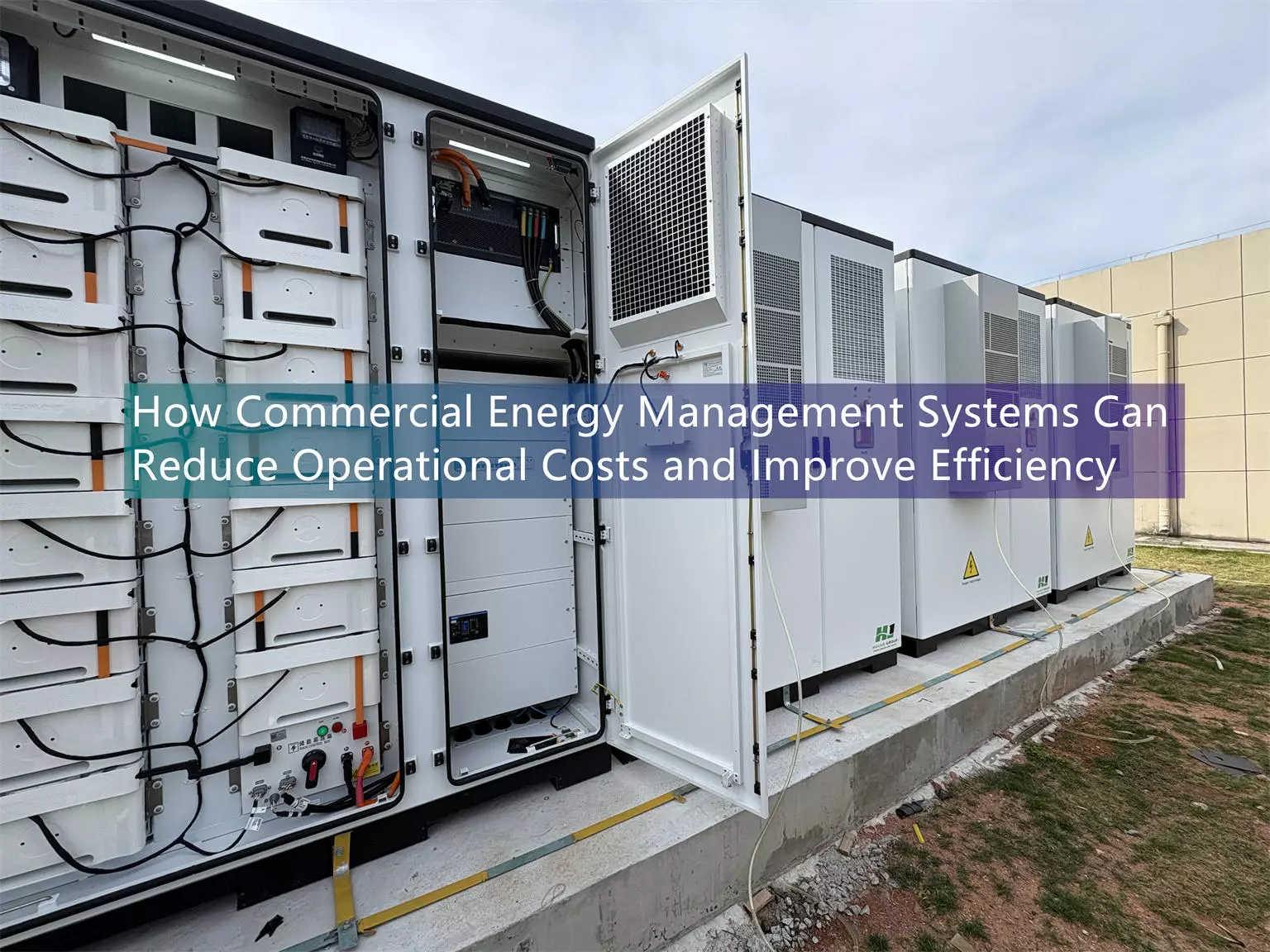

What is a lithium battery storage container?

It’s basically a giant “power bank” for your factory. Inside the container, there are high-capacity lithium batteries, an energy management system (EMS), and supporting equipment like inverters and cooling systems. It can store power when electricity is cheap, and release it when demand is high.

Think of it as a buffer between your factory and the grid.

How does it help with demand management?

-

Peak shaving

Factories often face peak demand charges from the utility company. These charges are based on your highest power usage in a billing cycle. With a lithium battery storage container, you can draw power from the battery during peak times instead of pulling it all from the grid. This lowers your peak demand and saves money.

Example:

If your normal load is 500 kW, but at 10 am it spikes to 800 kW, the battery can supply the extra 300 kW. Your demand meter never sees the spike. -

Load shifting

Electricity prices can vary throughout the day. At night, it’s often cheaper. You can charge the battery when rates are low, and discharge during expensive daytime hours. This is especially useful in places with time-of-use (TOU) tariffs.

-

Backup power

Unplanned outages can stop production and cause big losses. A lithium battery storage container can act as backup power. It switches on instantly, so your machines keep running while the grid is down. No need to wait for a diesel generator to start.

-

Smoother operations for renewable energy

If your factory uses solar panels, production can drop suddenly when clouds pass. The battery can step in to fill the gap, keeping your supply stable. That means fewer interruptions and more efficient use of your solar power.

Why lithium batteries?

- High efficiency — Over 90% round-trip efficiency means less energy wasted.

- Fast response — They can deliver power in milliseconds, which is critical for peak shaving.

- Long life — Modern lithium batteries can last thousands of cycles with minimal capacity loss.

- Compact size — A containerized system can store a huge amount of energy in a small footprint.

Real-world results

A manufacturing plant with large motors installed a 1 MWh lithium battery storage container. Before, their monthly demand charge was $12,000. After using the system for peak shaving, they cut that by nearly 30%. Over a year, the savings covered a big part of the investment cost.

The bottom line

A lithium battery storage container is more than just an energy storage device. It’s a tool for cost control, efficiency, and reliability. For factories, it can mean lower bills, fewer outages, and smoother operations. As energy prices keep changing, having your own power buffer isn’t just smart — it’s becoming essential.

Find Your Solar + Battery Storage Specialist Now!

* Fill out this form and our experts will help you find the perfect solar storage solution for your home or business.