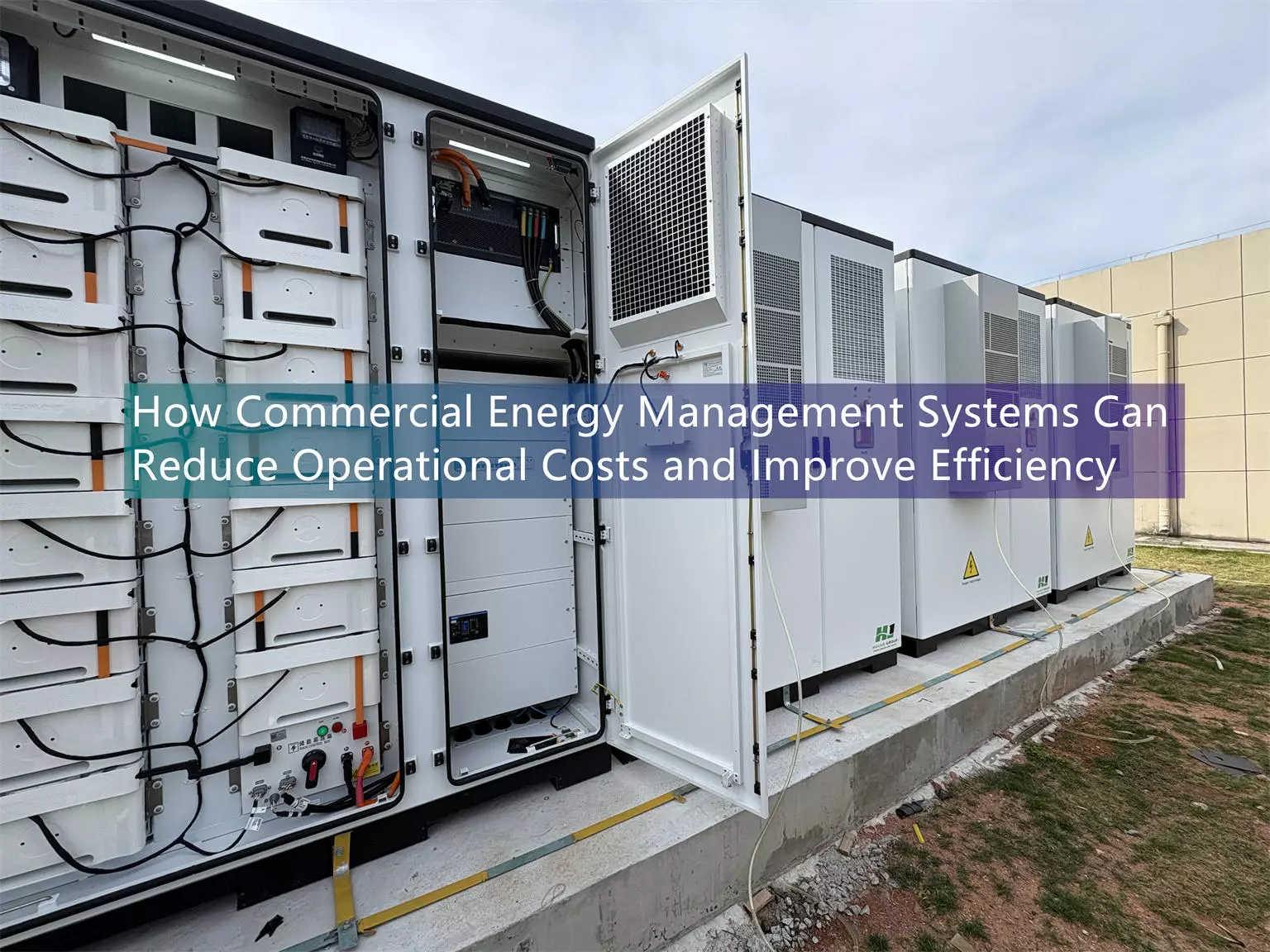

How Commercial Energy Management Systems Can Reduce Operational Costs and Improve Efficiency

For facility managers, the utility bill has transformed from a fixed operational cost into one of the most volatile expenses—and, simultaneously, the greatest opportunity for control and savings. In our work with manufacturers, we’ve seen that peak demand charges alone often account for 30-50% of the total electricity cost. This makes commercial energy management system costs a critical consideration, especially when factoring in the price of Commercial & Industrial (C&I) EMS solutions for large operations. Sure, sustainability goals get the headlines, but when the board asks for the business case behind a EMS, the conversation gets real: “What’s this going to cost us, and when will we see our money back?”

Unlike off-the-shelf general-purpose software, an EMS in the commercial and industrial (C&I) sector is a layered investment. To get an accurate estimate, you must look beyond the initial quote and understand the interplay between hardware, intelligent software, and long-term integration.

1. Three Dimensions of Commercial Energy Management System Investment

When evaluating C&I EMS pricing, it’s helpful to think of the system as a “three-story building”: without the “foundation” (meters and sensors), you can’t gain “visibility” (data insights).

A. Physical Layer (Hardware and Sensing)

This is where the data originates. This cost depends entirely on how “deep” you want to understand your operations.

- Main Metering: High-level tracking of total consumption for the entire facility.

- Sub-metering: Monitoring specific production lines, HVAC chillers, or data center racks.

- IoT Gateway: The bridge hardware connecting physical devices to the cloud.

Typical Cost: For large factories, hardware alone can range from $25,000 to over $100,000, depending on the number of monitoring points.

B. Intelligence Layer (Enterprise Energy Software Costs)

Enterprise energy software costs typically consist of an initial setup fee and recurring SaaS (Software as a Service) subscription fees. These costs are integral to the success of any C&I EMS and vary depending on the scope and scale of the energy management required. As businesses scale up their energy operations, they must also consider the long-term costs associated with enterprise energy software and how those costs evolve over time.

- Core Brain: This platform processes thousands of data points, designed to identify and alert you before peak demand events occur.

- Recurring Costs: Annual subscriptions typically cover cybersecurity updates, cloud storage, and AI prediction modules.

C. Human Layer (Integration and Engineering)

This is the most easily overlooked part of the budget. You’re not just buying software, but a system that must “talk” to your existing infrastructure. This involves electrical engineering, custom API integration, and employee training.

2. Cost Estimates for Different Sized Facilities

To help you budget, here are typical market price ranges for commercial and industrial installations:

| Cost Component | Medium-Sized Facility (Retail/Office Building) | Large Industrial Plant/Data Center |

|---|---|---|

| Initial Hardware | $5,000 – $15,000 | $30,000 – $120,000+ |

| Setup and System Integration | $10,000 – $25,000 | $50,000 – $150,000+ |

| Monthly SaaS/Support Fee | $200 – $800 | $1,500 – $5,000+ |

| Total First-Year CapEx (Capital Expenditure) | $20,000 – $50,000 | $100,000 – $300,000+ |

Note: These are estimates only. Final large-scale monitoring prices depend on the complexity of the local power grid and the age of existing electrical panels.

3. Maximizing Return on Investment (ROI) Through Strategic Integration

An EMS is most valuable when it goes beyond simply “observing” energy and actively “manages” it. This is especially important if you are integrating on-site renewable energy or energy storage systems.

- Optimizing Energy Storage: If you deploy a battery system, the EMS is key to calculating how much money you save. As we noted in our 2024-2025 Battery Energy Storage System (BESS) Cost Guide, the “intelligence” of the system directly impacts your Levelized Cost of Storage (LCOS).

- Calculating Solar PV Returns: Real-time data provided by EMS can be used to verify your Levelized Cost of Energy (LCOE), ensuring your solar PV investment meets expected returns.

4. Case Study: Transformation of a Latvian Coastal Industrial Base

Let’s ground this with a story from the field. On the Baltic coast of Latvia, a major industrial player was sitting on a new 2.5MW/4MWh battery asset but was nervous about its complexity. Their challenge wasn’t just storage—it was managing wild swings in regional grid frequency and predicting price spreads in a volatile power market. By deploying an EMS with dedicated algorithms for arbitrage and frequency regulation, the system didn’t just save costs; it started generating direct revenue by selling grid stability services. The project turned a capital expense into a profit center, with payback accelerating thanks to those stacked value streams.

- Challenge: Significant energy fluctuations and strict requirements for grid stability.

- Solution: HighJoule provided a powerful EMS to coordinate two 2MWh battery containers and their associated power conversion systems (PCS).

- Result: The EMS enabled energy arbitrage (buying and storing electricity when prices are low, and using it when prices are high) and frequency regulation. The energy system transformed from a cost center into a revenue-generating tool, demonstrating that the right EMS can achieve ROI in just 3-5 years.

Learn more about similar projects in our global case study library.

5. Why “Cheap” Systems Often Cost More

When comparing quotes—especially for C&I EMS—beware of “black-box” solutions with proprietary, closed architectures that lack long-term support. These low-cost options often appear attractive at first glance but can result in hidden costs down the line, especially when it comes to the enterprise energy software cost and system integration. It’s crucial to consider the full cost of ownership, including the complexity of large-scale monitoring and long-term service requirements. Low initial costs for commercial energy management systems can quickly skyrocket if:

- Integration fails: The software cannot communicate with your specific brand of air conditioners or inverters.

- Lack of support: The system fails during peak demand periods, and 24/7 technical support is unavailable.

- Data silos: The system is not scalable, forcing you to buy a completely new system when you add solar PV or charging stations three years later.

HighJoule fills this market gap by providing localized services, 24/7 technical monitoring, and a “hardware-agnostic” platform designed for business growth.

Summary

The upfront cost of a commercial energy management system (EMS) often masks its true value as a long-term profit driver. While the upfront capital for C&I installations is substantial, the real ROI stems from aggressively tackling peak demand charges—the single largest line item for most industrial energy users. By bridging the gap between initial expenditure and automated demand response, these systems transform energy from a fixed overhead into a manageable, strategic asset.

Find Your Solar + Battery Storage Specialist Now!

* Fill out this form and our experts will help you find the perfect solar storage solution for your home or business.