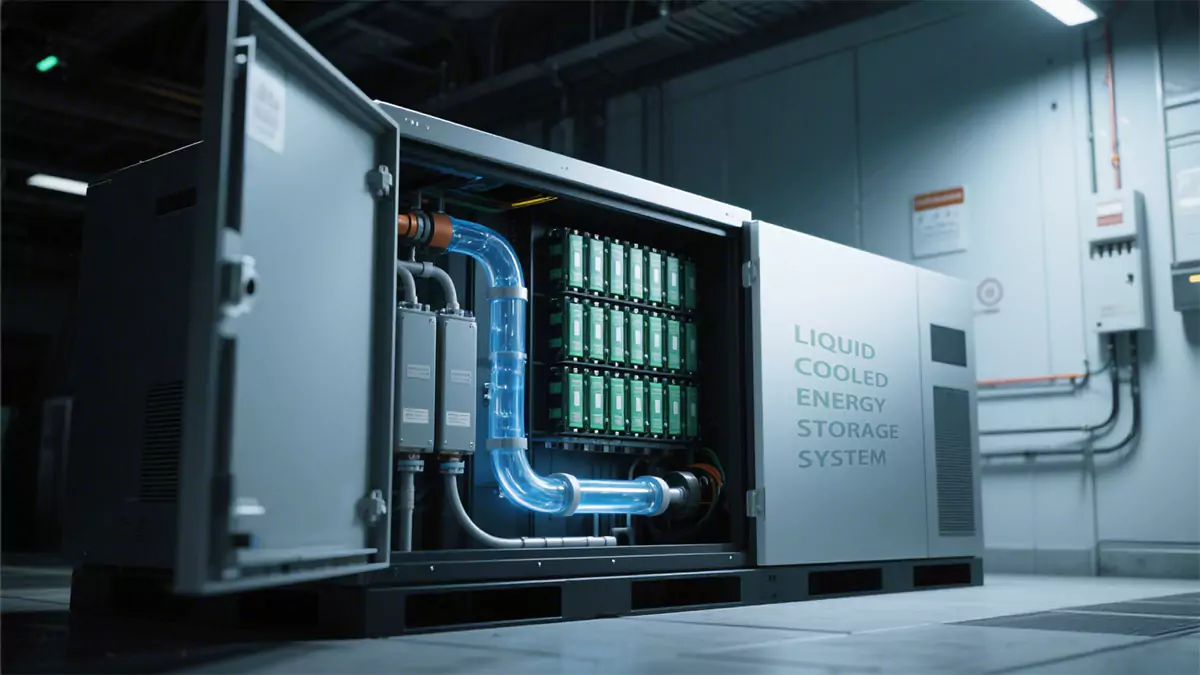

What Is a Liquid Cooled Energy Storage System?

Have you ever wondered how modern energy storage systems handle extreme heat during high-performance operations? Liquid cooled energy storage systems represent a breakthrough technology that is transforming large-scale battery management. By circulating liquid coolant directly through or around battery modules, these systems maintain optimal operating temperatures—offering significant advantages over traditional air-cooled alternatives.

The Thermal Management Challenge in Energy Storage

As battery packs increase in capacity and energy density, thermal management becomes a critical design factor. Conventional air cooling struggles to maintain uniform temperatures across large battery arrays, leading to several issues:

- Reduced battery lifespan — Up to 30% faster degradation under high temperatures

- Safety hazards — Risk of thermal runaway and fire incidents

- Limited charging speeds — Heat buildup forces systems to throttle performance

Without effective cooling, performance, safety, and reliability are compromised—especially in utility-scale deployments or hot climates.

How Liquid Cooling Outperforms Traditional Methods

Compared to air-cooled systems that only manage 20–30% thermal efficiency, liquid cooling achieves over 90% thermal transfer efficiency through several key innovations:

- Integrated Cooling Plates: Coolant flows through aluminum or copper plates embedded between battery cells, enabling fast and uniform heat extraction at the source.

- Use of Dielectric Fluids: These electrically non-conductive liquids safely circulate close to sensitive electronics without risk of short circuits.

- Smart Pump Control: Advanced sensors and controllers adjust coolant flow in real-time, maintaining consistent temperature across every module.

The result? Faster charging, longer battery life, and safer operation—even under peak load or harsh weather conditions.

Real-World Implementation: The Arizona Solar Farm Case

In May 2025, the 250MWh HighJoule Energy Project became North America’s first fully liquid-cooled battery energy storage facility.

Operating under ambient temperatures up to 45°C, the system maintains cell temperatures within ±2°C of the optimal setpoint—something air-cooled systems could never achieve in such environments. According to project engineers:

- Battery lifespan increased by 18%

- System downtime due to overheating dropped to near zero

- Charging throughput improved during midday peak hours

This case underscores the reliability and real-world benefits of liquid cooling in harsh climate zones.

Why This Matters for Energy Investors and Project Developers

In a competitive energy landscape, liquid cooling isn’t just a technical upgrade—it’s a strategic business decision. Consider the advantages:

- Lower Operating Costs: Reduced thermal stress means fewer battery replacements and lower maintenance needs.

- Improved System Uptime: Consistent temperatures help avoid derating and thermal faults.

- Regulatory Compliance: Enhanced fire safety and thermal control make it easier to meet grid and insurance standards.

- Higher ROI: Greater energy throughput and extended asset lifespan improve your investment yield.

Whether you’re building a solar + storage farm or upgrading a commercial BESS installation, liquid cooling helps future-proof your system against rising demand and climate stress.

The Future of Thermal Management

As battery chemistries push beyond 300Wh/kg and systems scale beyond GWh, liquid cooling will move from optional to essential. Looking ahead, innovations like phase-change materials and hybrid cooling loops may cut cooling energy usage in half—while further extending system life.

The question is no longer “Should we adopt liquid cooling?”

It’s “How fast can we scale it to meet tomorrow’s energy storage needs?”

Find Your Solar + Battery Storage Specialist Now!

* Fill out this form and our experts will help you find the perfect solar storage solution for your home or business.