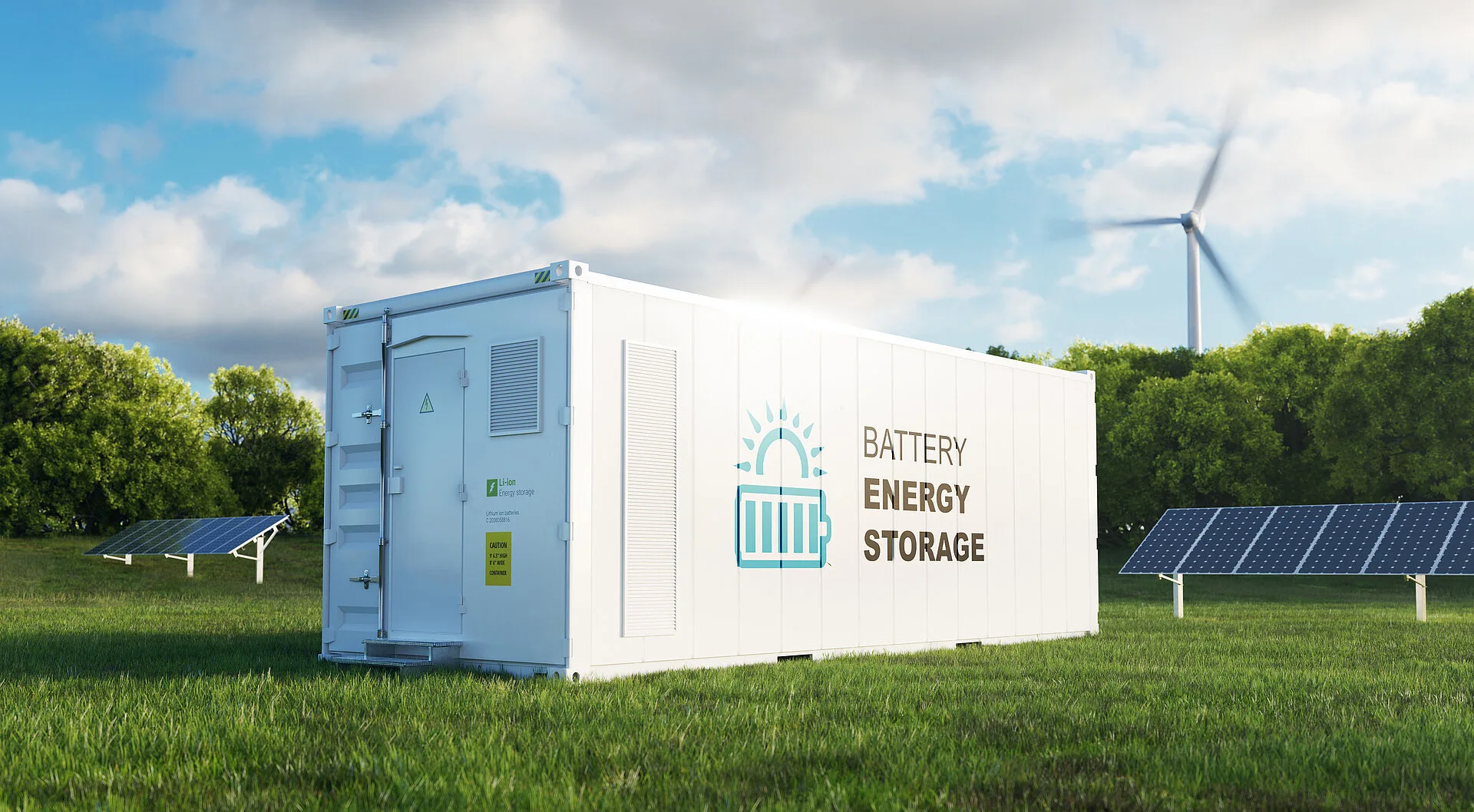

The project involves the installation of a rooftop solar system at a mechanical manufacturing factory in San Francisco, California, USA, aimed at reducing energy costs and promoting environmental sustainability.

Project Introduction

In San Francisco, California, a mechanical manufacturing factory built a rooftop solar system to reduce energy costs and promote environmental sustainability. The project started in March 2024, was completed and connected to the grid in July, and is now operating steadily with significant results.

Project Details

The factory’s rooftop covers an area of 10,000 square meters. The photovoltaic system has an installed capacity of 1.2 MW, with 3,000 monocrystalline silicon solar panels and high-efficiency hybrid inverters.

The system is designed to last for 25 years, with the first-year power generation exceeding 1.5 million kWh, and the annual power generation degradation rate is controlled within 0.5% to 0.7%.

Applications

The generated electricity is primarily used to power the factory’s stamping, welding, and painting production lines, meeting 35%-40% of the factory’s electricity demand. The remaining electricity is used for office lighting, air conditioning, and charging facilities, significantly reducing electricity purchased from the California grid.

For example, during weekdays when the production lines are operating at full capacity, the photovoltaic system can simultaneously power 20 large stamping machines and 30 welding robots, reducing grid load during peak electricity demand periods in the workshop.

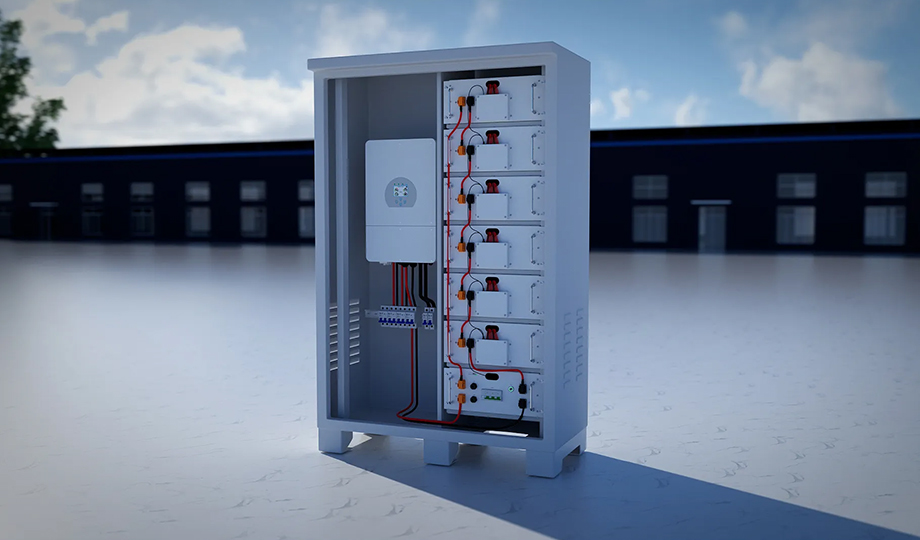

Main Equipment

Photovoltaic Panels: Monocrystalline silicon panels with a conversion efficiency exceeding 21% and excellent anti-PID degradation performance, ensuring stable power generation even in San Francisco’s foggy climate.

Inverters: High-efficiency hybrid inverters with a maximum conversion efficiency of 99%. They feature smart arc detection and protection functions, allowing real-time monitoring of panel operating status and fault point identification.