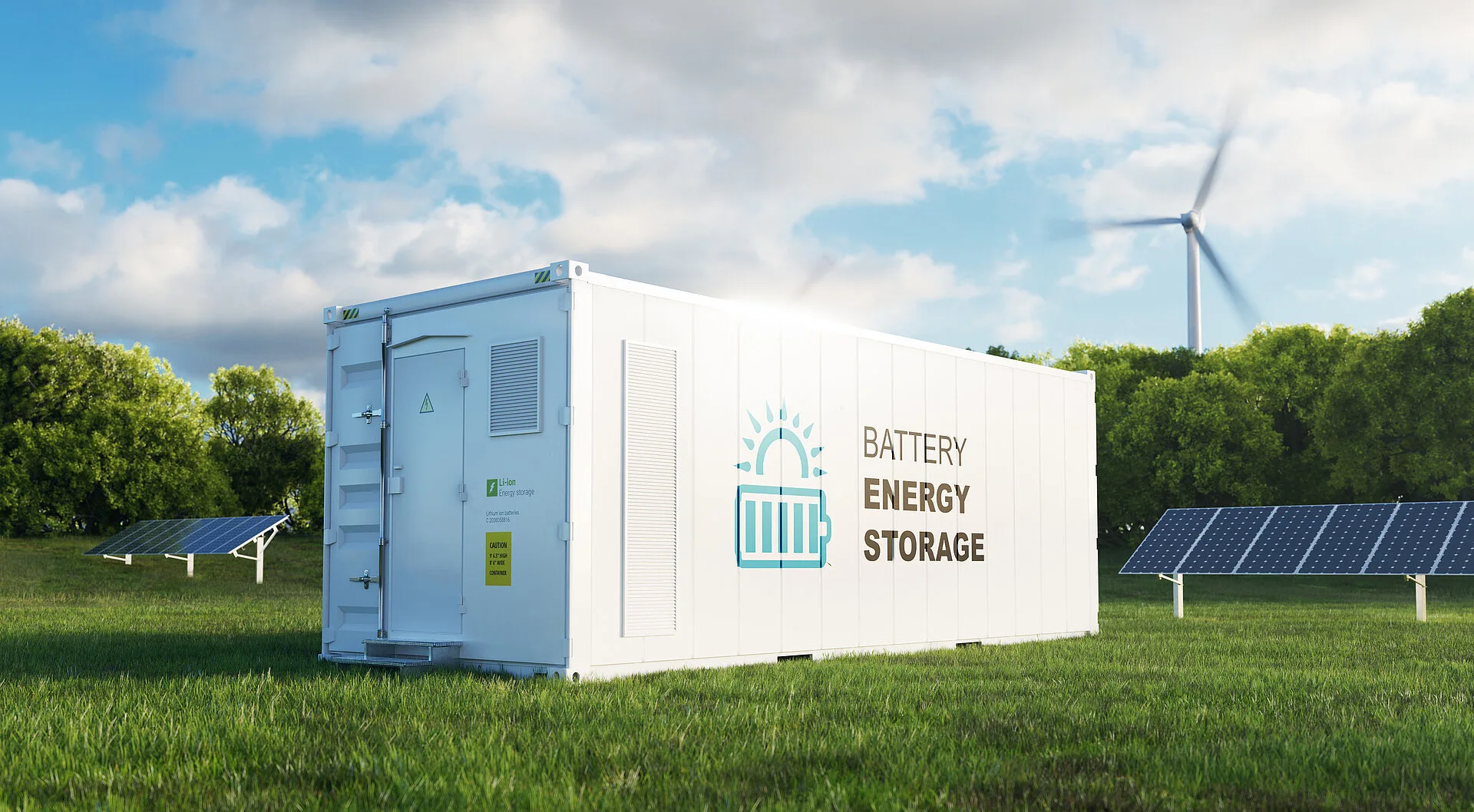

The project involved the installation of a 300kW photovoltaic power generation system on the rooftop of a textile factory in an industrial park in Myanmar, effectively alleviating the factory’s electricity pressure. By utilizing the factory rooftop, it reduces production operating costs and increases energy self-sufficiency.

Project Introduction

In an industrial park in Myanmar, a textile factory has built a 300kW photovoltaic power generation system on its rooftop to reduce production operating costs and increase energy self-sufficiency, effectively alleviating the factory’s electricity pressure.

Project Details

The factory’s rooftop covers an area of approximately 3,000 square meters. The photovoltaic system uses monocrystalline silicon solar panels, with a total installed capacity of 300kW.

The photovoltaic panels are installed at a 20° tilt, taking into account the local latitude and solar radiation angles to maximize power generation efficiency.

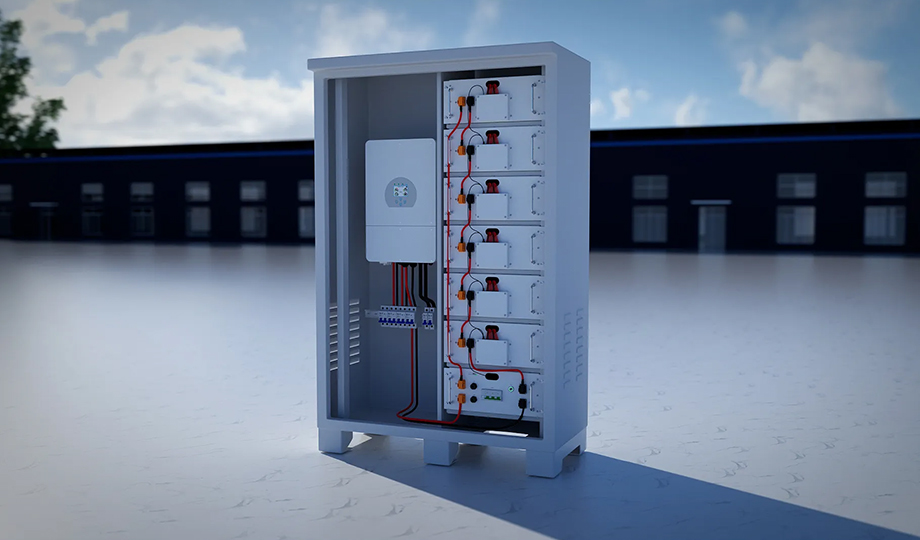

The system is equipped with six 50kW string inverters, integrated into the factory’s 400V distribution system.

The project has a design life of 25 years, with an estimated annual power generation of 420,000 kWh and an average annual utilization of approximately 1,400 hours.

Applications

The electricity generated is primarily used for the factory’s production equipment, lighting system, and office devices. During the day, when sunlight is abundant, the photovoltaic system meets 50% to 60% of the factory’s electricity needs, with the remaining power supplied by the local grid. This reduces the adverse effects of grid failures or power outages on production. Additionally, the photovoltaic system helps alleviate the pressure on the local grid during peak electricity demand periods.

Main Equipment

Photovoltaic Panels: Monocrystalline silicon solar panels with high conversion efficiency, excellent anti-degradation performance, and good low-light performance, ensuring stable power generation in Myanmar’s variable climate conditions.

Inverters: With a maximum conversion efficiency of 99%, the inverters feature smart arc detection and protection functions, enabling real-time monitoring of panel operating status and fault point identification.